Diagnosis, classification and recycling of photovoltaic systems

PV DiKlaWi

Currently, more PV systems than ever are being installed in order to achieve the ambitious target of the Renewable Energy Expansion Act of an additional 11 TWh of electricity from PV by 2030. At the same time, some PV systems in operation are already being dismantled or replaced by more powerful modules, even though some of them have not yet reached the end of their technical life cycle.

The PV DiKlaWi project team has therefore set itself the goal of preventing this premature retirement of functioning PV modules. This is to be achieved by means of a new diagnostic procedure based on electroluminescence, which makes it possible to obtain a more precise picture of the condition of installed PV modules. The modules will then be classified and, depending on their actual condition, either remain in operation, be given a further use (second life), or be recycled. This extends the service time, increases added value and conserves valuable resources in the fight against the climate crisis.

The first PV systems were installed more than 20 years ago and do not produce the power that a new system would. Especially for large-scale plants, it is common practice to replace all modules at the same time, without taking into account the different condition of individual modules. However, since the generation of the modules has the greatest environmental impact in their life cycle, it would make sense to maximize the lifespan of the modules. Only when this is no longer possible should modern recycling processes be used to recover many of the raw materials used. In terms of the waste hierarchy, extending the useful life, as well as reuse, is always preferable to recycling.

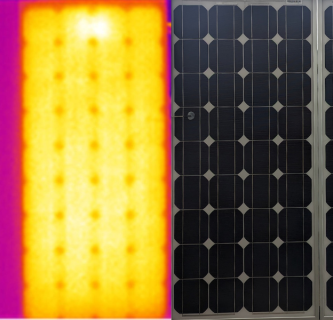

State-of-the-art is the inspection of PV systems with infrared cameras for hot spot detection. However, this method is influenced by environmental parameters and can only detect large-scale defect patterns. The electroluminescence approach is an innovative and much more informative method. Here, electricity is fed into the PV modules at night so that they begin to radiate in a certain frequency range (luminescence). This makes it possible to visualize defects (cracks, fractures, delaminations) down to the cell level. On this basis, a system will be developed in the course of the project that, in combination with Domain-Informed AI algorithms, will reliably diagnose the condition of modules.

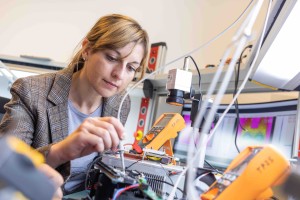

This diagnostic method will be developed and tested in the laboratory for subsequent validation on real PV systems. The camera intended for imaging will also be remotely controlled through the use of drones to enable inspection of modules in hard-to-reach locations. The combination of these remote-controlled cameras and evaluation using AI should enable reliable damage analysis. Only defective PV modules are to be recycled in the sense of the circular economy, while aged but still functional modules are to be made available for a second phase of use in the context of social projects.

The project consortium consisting of the Institute of Energy, Transport and Environmental Management at FH JOANNEUM and the Institute of Software Technology at Graz University of Technology aims to make a contribution to the circular economy and climate protection in the energy sector. The team is also supported by students.

The goals of the project are therefore:

- Development of a camera system and a diagnostic method in the EAS laboratory for fault detection on PV systems for field use.

- Testing of the diagnostic method on real PV systems of industrial cooperation partners

- Development of a domain-informed AI algorithm to classify the condition on the images produced

- Creation of a fault catalog by means of analysis and verification of the recordings of found damage patterns

- Avoiding the premature return of functional PV modules

- Identification of possibilities for reuse of degraded PV modules