Reinforced Thermoplastic Composite Wing Movable Structures

RTCWinMoSt

The RTCWinMoSt project is about fiber-plastic composites made of thermoplastic matrix system. The aim was to create a design concept for a landing flap of the DA62 aircraft type from Diamond Aircraft Industries GmbH. In addition to the Aviation Institute of FH JOANNEUM, the project partners are PRIME aerostructures GmbH as consortium leader, TCKT - Transfercenter für Kunststofftechnik GmbH and Diamond Aircraft Industries GmbH.

The project, funded by the Federal Ministry for Transport, Innovation and Technology as part of the FTI program TAKE OFF, is being carried out by the Austrian Research Promotion Agency.

Aircraft construction places high demands on structural design and quality of structural components. Aircrafts must have a low dead weight, high loading capacities and long lifecycles while meeting numerous aviation requirements regulating primary structural components. In addition to criteria such as high strength and rigidity, temperature and corrosion resistance, suitable components must be low in specific weight. Due to their excellent property profile, high-performance materials such as carbon fiber reinforced plastics (CFRP) have firmly established themselves in the aviation industry.

The aim of the RTCWinMoSt project was to use thermoplastics as a matrix material in aerospace components. The technological focus of the consortium was on developing these new composite materials for a wider range of applications, especially in the area of wing moveables and primary structural components. Another important aspect in addition to the mechanical properties is the economy in production and operation.

Problem

For the production of structural components from a fiber-plastic composite (FRP) in aviation, primarily epoxy resin (thermoset) is used as a matrix. A big advantage, in addition to the good mechanical properties, is the ease of processing and many years of experience. For the processing of epoxy resin, a chemical crosslinking reaction is started by mixing resin and hardener; the solid molding material is finally created through the crosslinking of the molecular chains. During the production of FRP, fibers are impregnated with the resin-hardener mixture. The hardening of the resin fixes, stabilizes and protects the fibers from the matrix, among other things.

Thermoplastics and thermosets differ primarily in the different cross-linking of the molecular chains, which is reflected in the secondary properties. These primary properties also require a full investigation and evaluation of the mechanical and thermal properties, as well as the possible processes for manufacturing the thermoplastic FRP

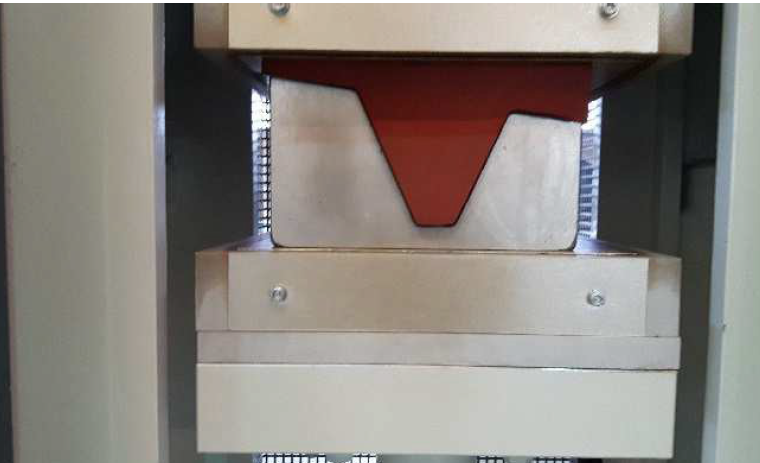

While thermoset matrix systems are created by crosslinking a liquid component, thermoplastic matrix systems are solid at room temperature and have to be heated to the melting temperature in order to be deformed. The melting temperature depends on the thermoplastic used and is about 390 °C for high-performance thermoplastics and between 200 °C and 300 °C for engineering thermoplastics. After forming at the melting temperature, the component is cooled in the mold to the solidification temperature. If the process steps of forming and cooling can be accelerated, cycle times of up to 5 minutes can be achieved.

Results

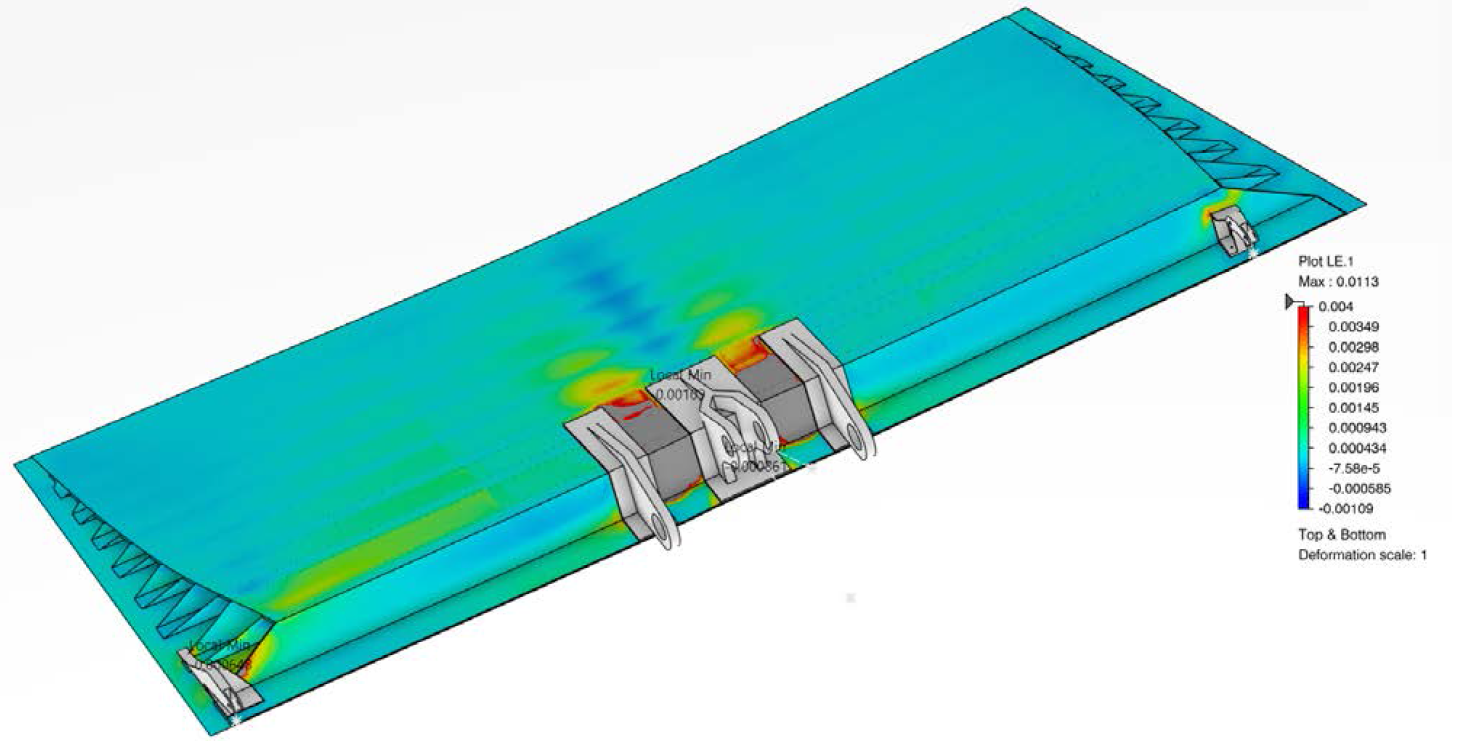

A specification sheet for the requirements for the thermoplastic matrix systems was developed based on a material and process study. A component from category CS23, a landing flap of the aircraft type DA62 from Diamond Aircraft Industries GmbH, was used for the design studies. The original design was adapted for a thermoplastic forming process, based on calculations, the optimized geometry for the manufacturing and joining process was determined.

Components made of PA6 and PA6.6 were manufactured.