6.5 billion tons – that’s how much material is processed every year in the metal, glass, ceramics, lime and cement industries. This comes at a high price: 19.2% of global CO₂ emissions come from this sector.

Replacing natural gas-fired burners with electrically powered PLASMA burners not only represents a technical advance in terms of efficiency and process quality for industrial smelting furnaces but also enables enormous CO₂ savings in these industrial processes.

The mission: climate-neutral aluminum smelting

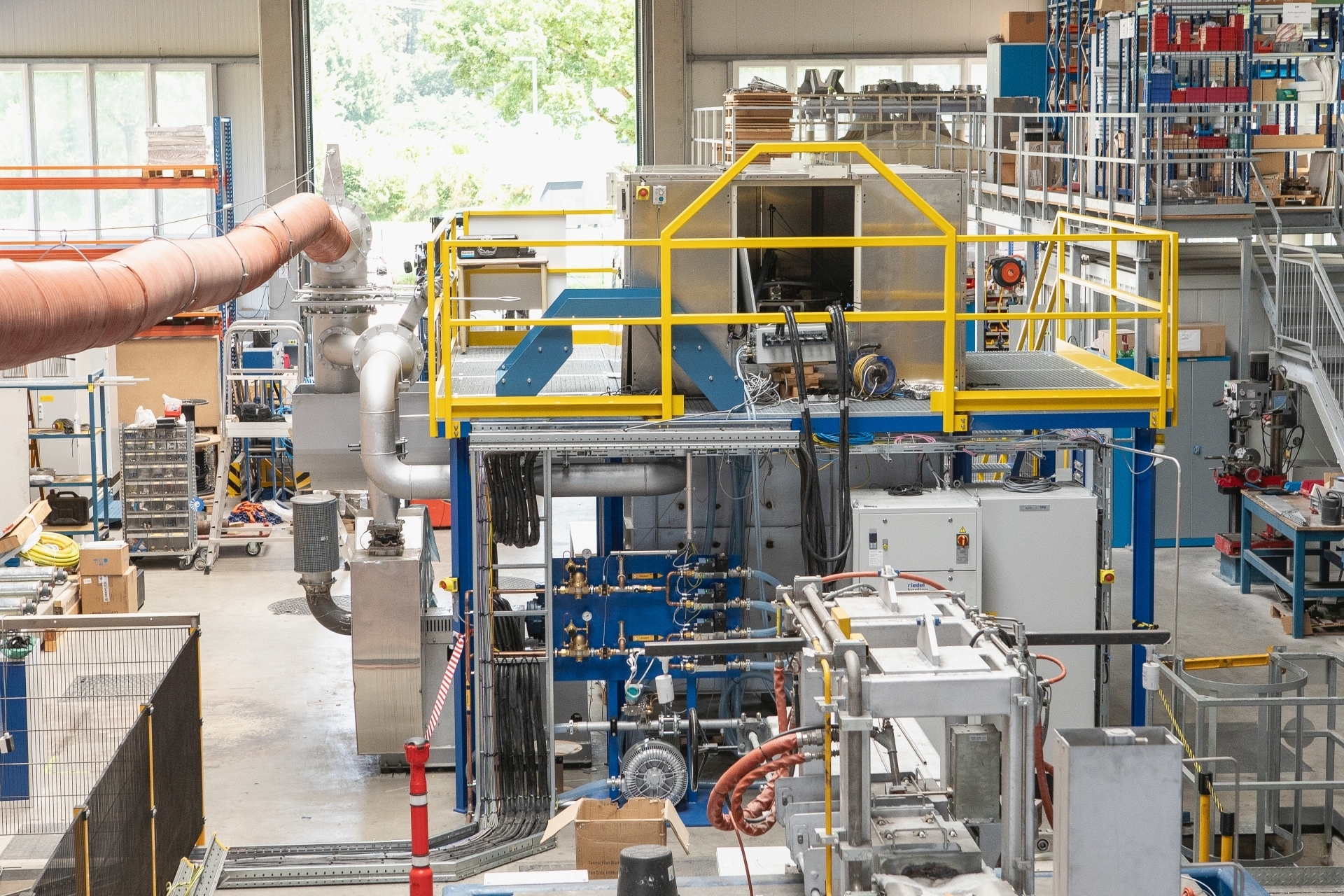

After comprehensive analysis, the TPS team has focused on introducing the new technology for smelting secondary aluminum—a key process in the circular economy. The goal: to replace fossil fuels with clean, efficient, and sustainable technology.

The solution is an electrically controlled plasma torch that not only provides power to the melting furnace, but can also be controlled very precisely, allowing the melting process to be optimized.

From idea to implementation

The path to achieving this goal is clearly defined:

- Design of the control unit

- Simulation and optimization

- Construction, testing and evaluation

Appropriate inductor coils are used to ionize gases (e.g., argon, nitrogen) via magnetic fields. These coils are placed over the fireproof gas pipes. The inductors are supplied with high frequencies via resonance circuits by power electronic converters. Depending on the power, the frequency range is in the RF range.

Generating such frequencies with outputs of up to over 1 MW per unit places special demands on the design of the converters. Modern wide-bandgap semiconductors with silicon carbide and gallium nitride now make it possible to replace conventional high-frequency power amplifiers with highly efficient power electronic converters. This also allows the previous power limits (typically <100kW) to be exceeded.

FH JOANNEUM began developing converters with wide-bandgap transistors back in 2012. Since then, its R&D projects have focused on exploring the limits of switching frequencies while maintaining high efficiency. The expertise built up over many years will now be put to comprehensive use in the ICPIH project in order to achieve output powers of over 1 MW even at high output frequencies. Compact size and high efficiency are once again seen as the primary design goals.

The power electronic converters for the ICPIH project are an excellent example of mechatronic systems as a complex combination of software (embedded and application-oriented), electronic hardware, and mechanics for cooling and general assembly technology.