Drivetrain test beds are used to examine individual components or assemblies. Single parts (such as a gearbox) or entire assemblies (gearbox, prop shaft and differential) can be assembled as complete drivetrains in a variety of test bed configurations. Configuration 2M indicates the use of two dynamometers. For example, one dynamometer can be connected to the gearbox input shaft and the second to the gearbox output shaft to simulate different transmission loads.

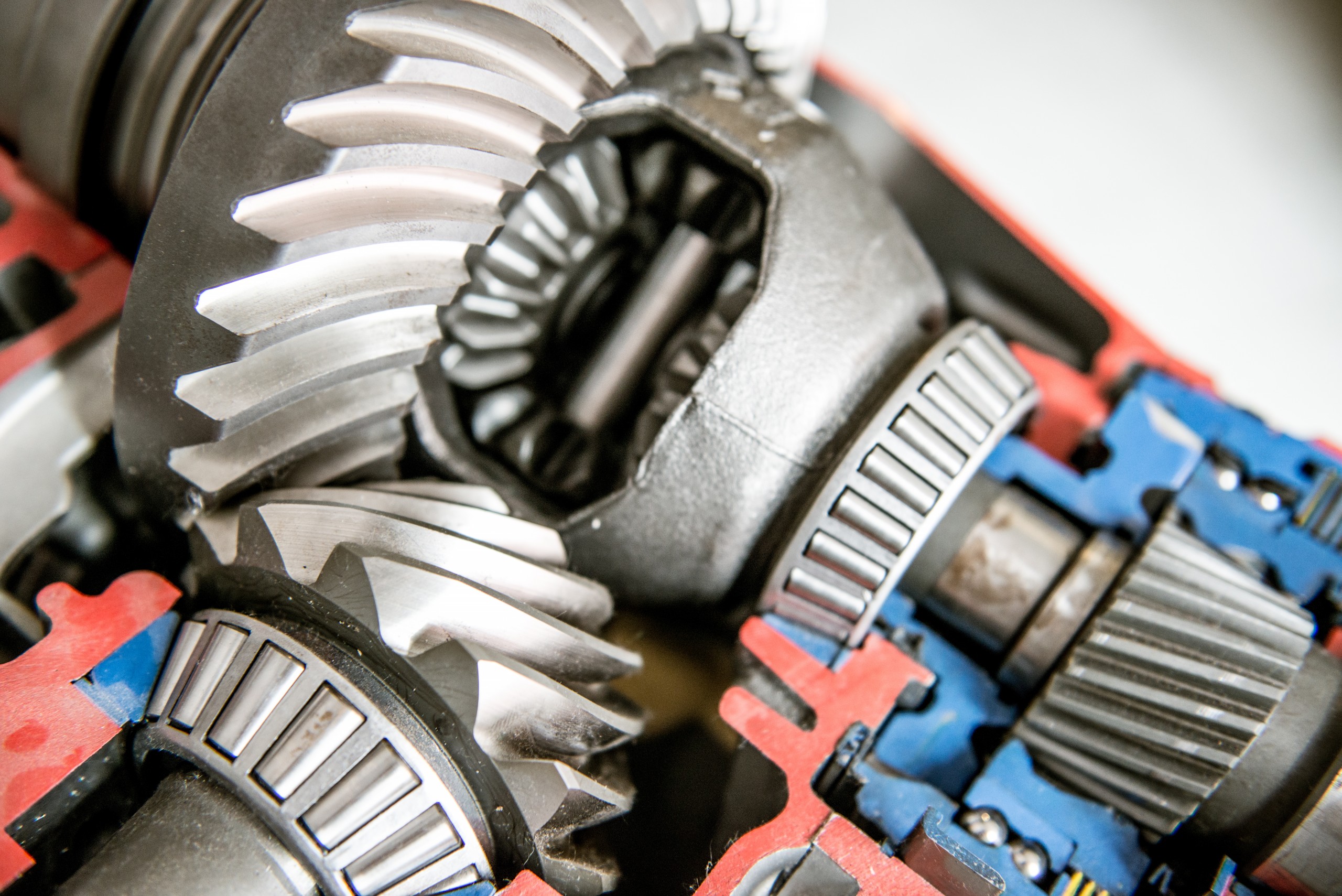

The 3M test bed is equipped with three dynamometers for measuring drive axles with differentials. For example, the prop shaft and the wheels of a powered rear axle can be replaced by dynamometers. This arrangement makes it possible to simulate a huge variety of loads, as when driving through curves. The dynamometers on the wheels simulate the road, while the dynamometer of the prop shaft simulates the engine. The tests can be performed on drivetrains of both combustion engine vehicles and hybrid or electric vehicles.