This includes implementing all interfaces to demonstrate digital production and end-to-end data integration, from ERP to the shopfloor and back. Following the Industrial Internet of Things (IIoT) approach, the disintegration of traditional 4-stage vertical integration is also examined. In this field our investigations are focused on determining which functions will in future be performed at which levels and by which services. Our research focus also lies on digital retrofitting as a potential means of ensuring the IP capability of machines of different ages and technologies.

Key research areas

- Which operative as well as strategic steps are necessary to facilitate networked production?

- What can be achieved by digitalising machines and equipment?

- How can traditional vertical IT integration along the automation pyramid be optimised, and what alternatives do IIoT scenarios offer?

- Which artificial intelligence methods are suitable for generating added value using prescriptive and predictive systems in the industrial environment?

- What are the future trends in digital production, and how can they benefit companies?

Use cases

- Digital retrofit using an X20 SPS to achieve IoT capability at field level

- WiFi location tracking for all assets and devices

- Real-time visualisation of machine data using dashboards

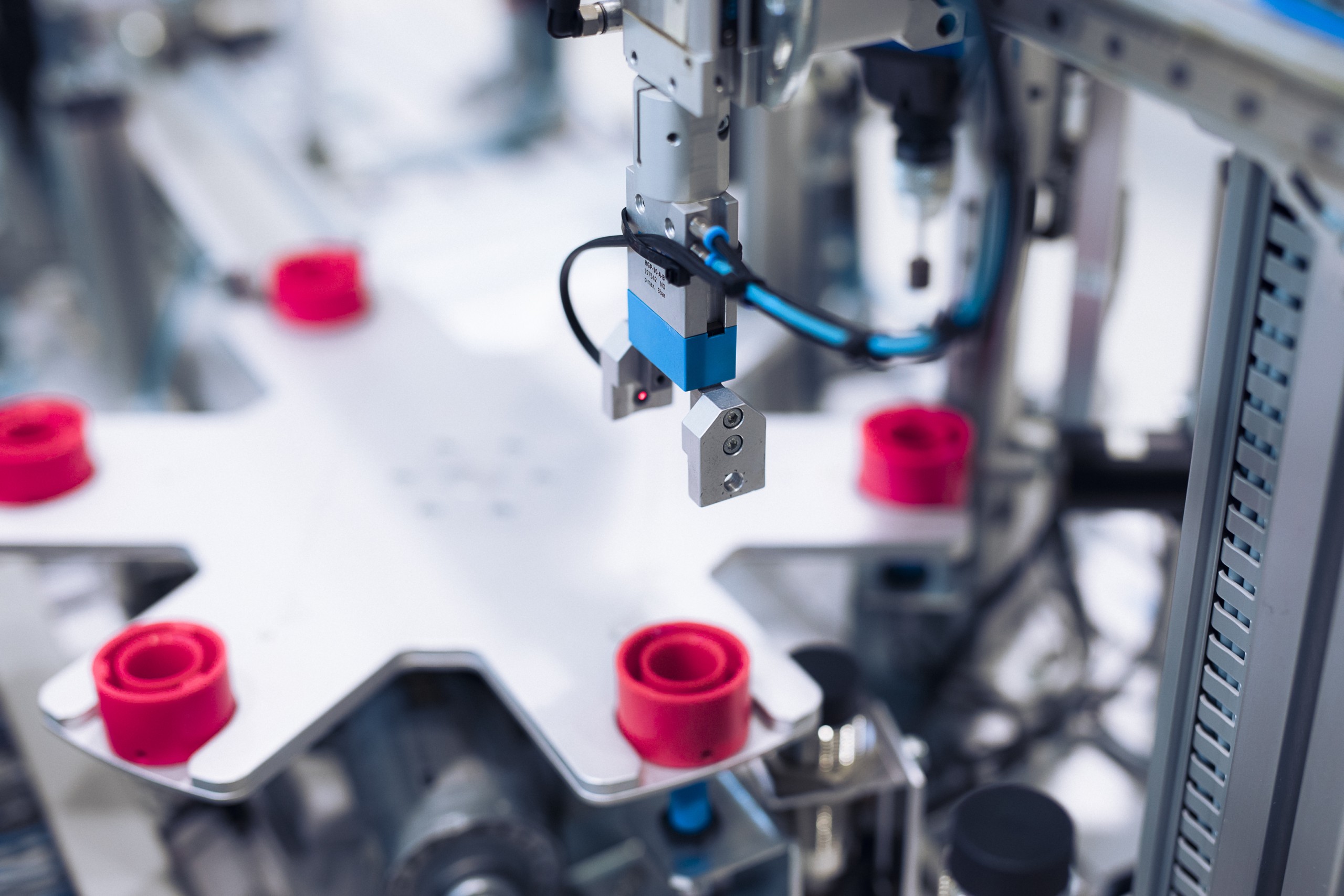

- Process optimisation using collaborative robots for assembling processes