eCULT – electrified Car Ultra Light Technologies

Developing an electric car

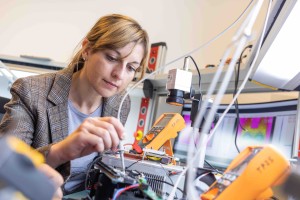

Electric vehicles are very much a part of the streetscape nowadays. Despite their growing popularity, electric vehicles’ share of the domestic market is still very small. To give students at the Institute of Automotive Engineering at FH JOANNEUM an insight into the technology of zero-emission cars, they developed their own electric vehicle during the course of a number of studies and projects.

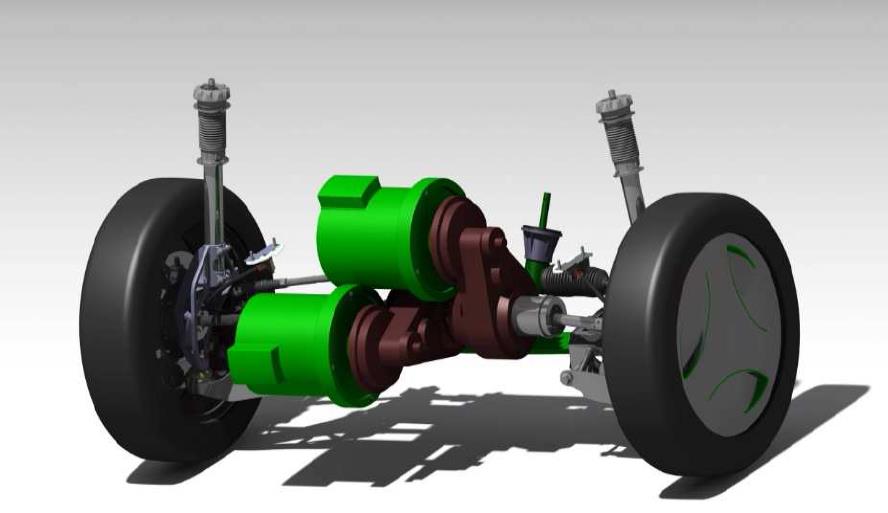

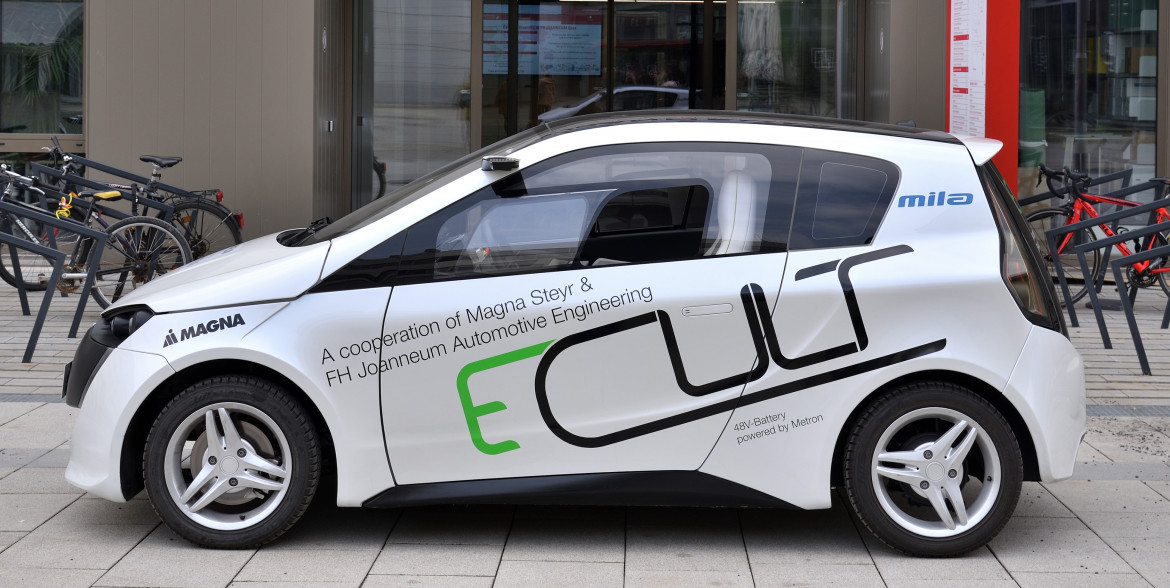

The first electric car to be built at FH JOANNEUM was based on a prototype from Magna in Graz. This extremely lightweight vehicle, designed as a city car, is powered by two 48 volt induction machines with a combined performance of 30 kilowatts or 41 PS.

Electric powered vehicles are enjoying growing popularity on the domestic market. Increasingly stringent environmental regulations and a change of thinking among the population are spurring on the market in electric cars. Growing demand and the increasing variety of different models and price brackets reveal that the electric car has become widely acceptable. Since this trend may herald an about-turn in the automotive industry, the Institute of Automotive Engineering is keen to offer its students the opportunity to acquire a thorough grounding in this area and to be actively involved in future innovations. This, in turn, offers the opportunity to distribute the tractive power so that vehicles can make tighter curves. In the current project status equal power is applied to both front wheels. In future projects this will be replaced with torque control, and even active power distribution, known as torque vectoring, where the torque applied to each wheel can be varied.

To offer all students the opportunity to actively work on this vehicle and also carry out modifications, a conscious decision was taken not to use high voltage components and to implement a 48 volt drive. Consequently students do not require special training to work with the fitted components and also the requirements placed on the workplace are less rigorous.

Further data as well as progress reports and test results are published on the website on a continuous basis. This gives you the opportunity to follow the development stages of the training and different projects.